Integration of CAD/BIM with SAP for a Midstream Gas Processing Plant

Project Summary A leading oil and gas company was tasked with developing a new gas processing plant. The engineering team relied heavily on off-the-shelf AutoCAD Plant 3D solu...

Project Summary

A leading oil and gas company was tasked with developing a new gas processing plant. The engineering team relied heavily on off-the-shelf AutoCAD Plant 3D solutions for design, while the operations and procurement teams used SAP S/4HANA for asset and material management. Disjointed systems led to inefficiencies, duplicated data, and costly delays. To address this, the InStandart team implemented a CAD-SAP integration solution that ensured seamless data flow between engineering and enterprise systems.

Business Challenges

The project faced several critical challenges:

- Data Silos: Engineering data (equipment specs, P&IDs, BoMs) resided in CAD/BIM tools, while procurement and maintenance data were managed in SAP.

- Manual Entry & Errors: Engineering Bill of Materials (EBoM) had to be re-entered into SAP manually, leading to error rates of 15% and lost time.

- Lack of Real-Time Visibility: Project managers lacked visibility into material availability and procurement status during design and construction phases.

- Delayed Handover: Asset handover from engineering to operations was delayed by 6+ weeks due to formatting and compliance issues.

Solution

Our company developed and implemented a custom CAD/BIM–SAP integration platform that included:

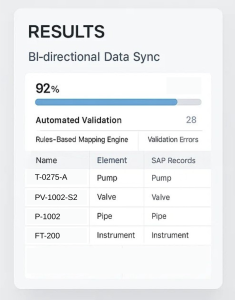

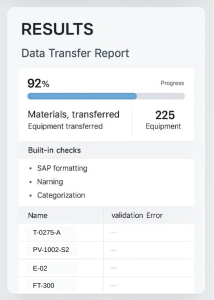

- Bi-directional Data Sync: Automatic extraction and synchronization of BoMs, equipment IDs, and asset metadata between AutoCAD Plant 3D and SAP S/4HANA.

- Mapping Engine: A rules-based mapping engine to convert CAD elements into SAP-compliant material master data and equipment records.

- Automated Validation: Built-in checks ensured that data met SAP formatting, naming, and categorization standards before transfer.

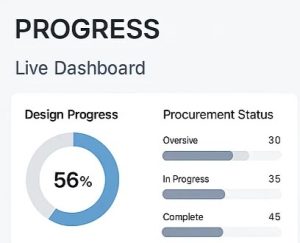

- Live Dashboards: Real-time tracking of design progress, procurement status, and asset readiness across both systems.

Results

The integration delivered measurable improvements:

| Metric | Before Integration | After Integration |

| BoM Data Entry Time | ~4 hours per package | < 15 minutes |

| Manual Data Errors | ~15% | < 2% |

| Engineering–Procurement Handover | 6+ weeks | 1 week |

| Asset Registration in SAP | ~10 days/project | Same-day registration |

| Total Engineering Hours Saved | N/A | ~1,200 hours/year |

Additional benefits:

- Improved collaboration between engineering and operations.

- Reduced procurement delays by 25% due to faster material planning.

- Seamless digital handover at commissioning phase.

- Enhanced traceability for audits and compliance.