The Intersection of CAD and Industry 4.0 in 3D Printing

Introduction In the evolving landscape of modern manufacturing, the confluence of computer-aided design (CAD) and Industry 4.0 technologies is revolutionising 3D printing. Thi...

Introduction

In the evolving landscape of modern manufacturing, the confluence of computer-aided design (CAD) and Industry 4.0 technologies is revolutionising 3D printing. This synergy is driving innovation, increasing efficiency, and creating new opportunities across industries. As we delve deeper into this intersection, it becomes clear how CAD and Industry 4.0 are working together to transform the additive manufacturing landscape.

Understanding CAD and Industry 4.0

Computer-aided design (CAD) is a cornerstone of technology in the manufacturing process. It involves using computer systems to create, modify, analyse, and optimise a design. CAD software enables engineers and designers to create accurate 2D and 3D models, facilitating the transition from concept to prototype and finally to production.

Industry 4.0, often referred to as the fourth industrial revolution, encompasses a range of advanced digital technologies. These include the Internet of Things (IoT), artificial intelligence (AI), machine learning, big data analytics, and cloud computing. Industry 4.0 aims to create “smart factories” where systems are interconnected and can autonomously communicate with each other to optimise manufacturing processes.

The Role of CAD in 3D Printing

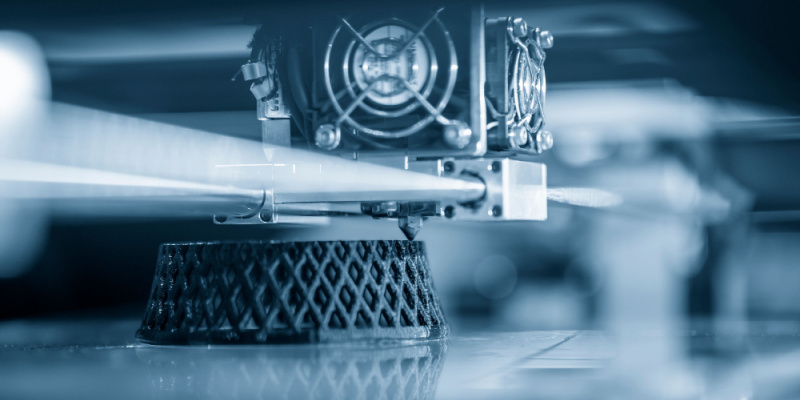

3D printing, or additive manufacturing, relies heavily on CAD to create digital drawings. These digital models are needed to guide the 3D printer as it creates the object layer by layer. The accuracy and detail provided by CAD software are critical to ensuring the quality and functionality of the final printed product.

Key benefits of using CAD in 3D printing include:

- Accuracy and fidelity: CAD software allows for the creation of highly detailed and accurate models, which is necessary to create complex geometries and intricate designs in 3D printing.

- Customisation and flexibility: CAD allows designers to easily modify and customise designs to suit specific requirements or preferences, facilitating rapid prototyping and iterative testing.

- Efficiency in design and manufacturing: By simulating the physical properties and performance of a design in a CAD environment, potential issues can be identified and addressed before actual printing, saving time and resources.

How Industry 4.0 Enhances 3D Printing

Integrating Industry 4.0 technologies with 3D printing takes additive manufacturing capabilities to the next level. Here’s how.

- IoT and intelligent connectivity: IoT devices embedded in 3D printers and manufacturing environments enable real-time monitoring and data sharing. This connectivity ensures that printers can autonomously adjust settings for optimal performance and detect issues before they become critical.

- Data analytics and AI: Advanced data analytics and AI algorithms can process massive amounts of data from the printing process, identifying patterns and insights that can lead to improved design and manufacturing strategies. AI can also predict maintenance needs, reducing downtime and increasing productivity.

- Cloud computing: Cloud platforms enable seamless sharing and collaboration on CAD files and 3D printing projects across multiple locations. This accessibility improves teamwork and speeds up the development process.

- Automation and robotics: Integrating robotics with 3D printing systems can automate the entire manufacturing process, from material handling to post-processing, increasing efficiency and reducing labour costs.

Conclusion

The intersection of CAD and Industry 4.0 in 3D printing is ushering in a new era of manufacturing. This convergence not only expands the capabilities and efficiencies of additive manufacturing, but also opens up new opportunities for innovation and customisation. As these technologies continue to evolve, their combined impact will undoubtedly drive further advances and change the future of manufacturing. Taking advantage of this synergy is essential for industries looking to remain competitive and capitalise on the opportunities presented by the fourth industrial revolution.