Automating Procurement Workflows Through CAD-Integrated AI Tools

Introduction In modern manufacturing and engineering, procurement is no longer just about buying parts and materials. It’s about efficiency, precision, and intelligent decisio...

Introduction

In modern manufacturing and engineering, procurement is no longer just about buying parts and materials. It’s about efficiency, precision, and intelligent decision-making. As industries embrace automation, CAD-integrated AI tools are redefining how procurement workflows function – transforming what was once a manual, time-consuming process into a smart, data-driven operation.

At InStandart, we explore how CAD-integrated AI tools can streamline procurement workflows, reduce costs, and minimize human error while ensuring that the right components are ordered at the right time.

Traditional Procurement Challenge

During product design and development, purchasing departments often face the same challenges:

- Manual data entry from CAD drawings into purchasing systems;

- Human errors in interpreting design specifications;

- Delays due to inconsistent component information or supplier constraints;

- Lack of real-time inventory and cost data visibility.

Each of these challenges complicates the design and manufacturing process. Once CAD models are developed, the next step – converting these designs into bills of materials (BOMs) and sourcing components – becomes a bottleneck unless automated.

Power of CAD-Integrated AI

By directly integrating CAD software with AI-powered procurement tools, companies can automate repetitive and error-prone steps. AI reads design data, interprets it in real time, and helps create accurate bills of materials and supplier proposals. This intelligent integration bridges the gap between design and procurement.

Here’s what makes this integration effective:

1. Automated Bill of Materials Generation

AI can instantly extract the necessary data from CAD drawings – part dimensions, materials, quantities, and specifications – to create a structured bill of materials. This eliminates the need for engineers to manually compile lists and ensures that all design changes are automatically reflected in procurement data.

2. Supplier Selection Recommendations and Cost Optimization

AI tools can connect to supplier databases or ERP systems, comparing part availability, pricing, and delivery times. As a result, companies can make data-driven procurement decisions based on supplier performance and real-time cost effectiveness.

3. Error Detection and Validation

AI systems can automatically identify discrepancies between design files and purchasing records, such as incorrect part numbers, incompatible materials, or obsolete components. This proactive validation prevents costly purchasing errors before they occur.

4. Inventory Forecasting and Demand Planning

Using predictive analytics, AI analyzes historical purchasing and production cycle data to forecast material demand. This ensures that purchasing accurately aligns with production schedules, reducing delays and minimizing excess inventory.

How Automation Benefits Businesses

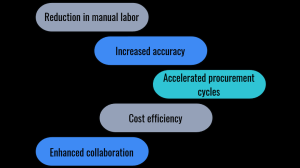

Integrating AI and CAD into procurement delivers significant operational and financial benefits:

- Reduction in manual labor: Engineers and purchasing teams spend less time on administrative work.

- Increased accuracy: Automated data extraction and validation reduce human errors during order processing.

- Accelerated procurement cycles: Real-time interaction between CAD, AI, and ERP systems accelerates sourcing decisions.

- Cost efficiency: Optimized sourcing and accurate forecasting reduce waste and unnecessary expenses.

- Enhanced collaboration: Design, engineering, and purchasing teams work with synchronized data and shared analytics.

Ultimately, automation doesn’t replace human expertise, but rather enhances it. Teams have more time to focus on strategic issues, innovate, and optimize processes.

Practical Use Cases in Engineering and Manufacturing

The combination of computer-aided design (CAD) systems and AI-powered procurement automation is already impacting various industries:

- Aerospace: AI-integrated CAD systems analyze complex components, recommending optimal materials and suppliers that meet stringent standards.

- Automotive: Manufacturers use CAD and AI tools to automatically identify interchangeable parts and cost-effective alternative components.

- Industrial Equipment: Automated procurement systems streamline the coordination of multiple suppliers in the design of complex equipment.

These examples illustrate how AI delivers accuracy and speed in industries where a single error can lead to costly production delays.

Implementation: The Road to Smart Procurement

To effectively implement AI-powered procurement systems integrated with CAD, companies should focus on:

- Choosing the Right Integration Tools: Ensure compatibility between existing CAD platforms (such as AutoCAD, SolidWorks, or CATIA) and AI-powered procurement or ERP systems.

- Data Standardization: Clear, well-structured design and procurement data is critical for accurate interpretation of AI data.

- Incremental Automation: Start by automating the creation and validation of bills of materials before expanding to supplier management or predictive ordering.

- Continuous Improvement: AI models are refined by data. Regularly refine algorithms based on procurement results and feedback.

Future of AI-Driven Procurement

As artificial intelligence technologies advance, procurement workflows will become more predictable, autonomous, and interconnected. Future computer-aided design systems will not only simulate designs but also model supply chain feasibility, estimate costs in real time, and automatically trigger procurement processes based on design updates.

This combination of intelligent design and procurement automation marks a significant step toward creating more intelligent manufacturing ecosystems, where time-to-market, cost efficiency, and accuracy reach new heights.

Conclusion

At InStandart, we believe that AI tools integrated into CAD systems are key to achieving new levels of procurement efficiency. By automating routine tasks and improving collaboration between design and procurement departments, companies can focus on innovation while maintaining operational excellence.

Automation is no longer optional – it has become the foundation of sustainable, intelligent manufacturing.