How Accurate 3D Models Enhance Product Development

Introduction In today’s fast-changing industries, product development needs to be accurate, flexible, and cost-effective. One tool that has revolutionized this process is the ...

Introduction

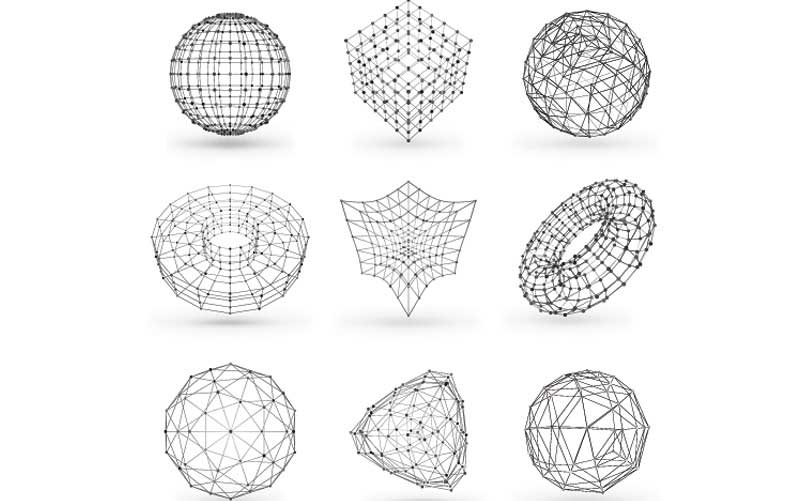

In today’s fast-changing industries, product development needs to be accurate, flexible, and cost-effective. One tool that has revolutionized this process is the 3D model. But not just any model – accurate and detailed 3D models are truly game-changers. They provide a visual and functional representation of products long before they take physical form.

As a result, teams can plan better, design smarter, and reduce costly errors. In this article, we look at several aspects of accurate 3D models.

From Concept to Reality

Product ideas typically start with sketches or basic concepts. However, these initial drawings often lack the depth needed for development. That’s where 3D modeling comes in. It bridges the gap between concept and reality.

With accurate 3D models, engineers and designers can visualize every angle, proportion, and component. This clarity helps teams understand how the product will function and fit in real-world conditions. What’s more, 3D models can simulate materials, lighting, and physics, making the design tangible even before a prototype is created.

Better Communication Across Teams

Effective product development involves multiple teams: design, engineering, marketing, and manufacturing. Miscommunication between these teams can lead to delays and errors. Accurate 3D models help solve this problem.

Instead of relying on complex technical drawings or abstract descriptions, teams can reference a single 3D representation. Everyone sees the same model with the same level of detail. This reduces miscommunication and ensures that all departments are aligned throughout the development cycle.

Additionally, stakeholders and customers can interact with 3D models. This helps them provide more accurate feedback, even if they do not have a technical background.

Speeding Up Prototyping and Testing

Traditional prototyping takes time. Creating a physical prototype is expensive and often requires multiple iterations. In contrast, 3D modeling allows for virtual prototypes. Teams can test form, fit, and functionality digitally.

For example, a mechanical part can be modeled and tested in a simulated environment. If a part doesn’t fit or interferes with another component, designers can instantly adjust the model. There’s no need to wait for a new prototype to be made.

This process speeds up development. It also reduces material waste and lowers manufacturing costs. That’s a big win for startups and large enterprises alike.

Supporting Design Optimization

Even the best ideas need refinement. During product development, small design flaws can lead to major problems later. Accurate 3D models allow for detailed testing and continuous improvement.

Designers can experiment with shape, size, texture, and material. They can quickly test different versions of a product. If something doesn’t work, they can go back to the model and make changes without starting over.

Moreover, advanced 3D modeling tools often include simulation functions. These tools test products under load, at changing temperatures, or in motion. They help identify weak points long before the product hits the market.

Improving Manufacturing Readiness

When a product goes into production, accuracy becomes even more important. Factories need precise dimensions and specifications. Mistakes at this stage can be costly.

Accurate 3D models help manufacturers understand exactly what needs to be built. They include detailed geometry, tolerances, and assembly instructions. As a result, production becomes faster, smoother, and less prone to errors.

In many cases, 3D models can also be fed directly into CNC machines and 3D printers. This allows for automated, high-precision manufacturing based on a digital drawing. There is little interpretation, and this significantly reduces risk.

Supporting Marketing and Sales Early On

Interestingly, 3D models aren’t just for engineers. Marketing and sales departments can use them, too – long before the product is ready.

Photorealistic renderings based on 3D models can be used in brochures, advertisements, and online catalogs. This helps generate excitement and gather feedback early on. In fact, some companies start selling or taking pre-orders based on these visuals.

In addition, interactive 3D experiences give potential customers the opportunity to explore products from all angles. This creates engagement and increases buyer confidence.

Enabling Customization and Personalization

Today’s customers want products that are tailored to their needs. 3D models make customization more efficient. For example, a company might offer a product with multiple configurations. The base model remains the same, but variations can be changed digitally.

This kind of flexibility would be difficult to manage with 2D drawings or manual design changes. With a reliable 3D model, teams can automate variations and keep everything consistent.

Industries such as furniture, fashion, automotive, and medical devices rely heavily on this approach. It helps them meet customer needs while staying within budget.

Reducing Time-to-Market

Ultimately, accurate 3D models shorten the development cycle. Better visualization leads to faster decisions. Virtual testing prevents physical rework. And seamless communication reduces delays.

Together, these benefits help companies launch products faster. In competitive markets, speed is critical. Being first can mean higher sales and stronger brand recognition.

Conclusion

Accurate 3D modeling is no longer a luxury – it’s a necessity in modern product development. It improves communication, reduces errors, speeds up design and manufacturing, and even supports sales.

Companies that use detailed and realistic modeling have a distinct advantage. They can innovate faster, reduce costs, and deliver higher-quality products. In an era where time, accuracy, and customer satisfaction matter more than ever, 3D modeling is the foundation for smarter development.