What is Industry 5.0 and How to Prepare for It

Introduction The industrial world has undergone significant changes over the past few decades, moving from manual production lines to highly automated, data-driven operations....

Introduction

The industrial world has undergone significant changes over the past few decades, moving from manual production lines to highly automated, data-driven operations. Following the widespread adoption of Industry 4.0, characterised by the integration of intelligent technologies, the industrial world is now preparing for the next leap: Industry 5.0. But what exactly is Industry 5.0, and how can businesses and professionals prepare for this new era?

In this article, we will look at the basics of Industry 5.0, its key drivers, how it differs from Industry 4.0, and practical steps businesses can take to prepare for it.

Understanding Industry 5.0: The Human-Centric Revolution

Industry 5.0 is often described as “collaboration between people and machines.” While Industry 4.0 primarily focused on digitalisation and automation through the use of AI, IoT (Internet of Things) and machine learning, Industry 5.0 takes it a step further by emphasising the role of people in the production process. This shift is more about personalisation, creativity and intelligent collaboration between people and machines.

The goal of Industry 5.0 is to create intelligent systems in which human ingenuity and technological efficiency work together. The focus shifts from automation alone to combining human creativity and critical thinking with the capabilities of machines, thereby creating value that would not be possible with automation alone.

Key Features of Industry 5.0

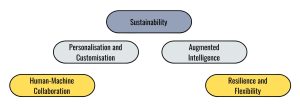

- Human-Machine Collaboration. One of the key differentiators between Industry 4.0 and 5.0 is the shift from full automation to collaborative robotics, also known as “cobots.” These machines work alongside human operators to enhance their work rather than replace them. By complementing human skills with technology, businesses can achieve higher levels of precision and customisation.

- Personalisation and Customisation. Industry 5.0 will push the boundaries of mass customisation. Thanks to advancements in AI and data analytics, products can be tailored to individual customer preferences. The collaboration between human creativity and machine learning enables a much more flexible and personalised production process, catering to specific user needs without sacrificing scalability.

- Sustainability. As the world moves toward more sustainable practices, Industry 5.0 integrates environmental responsibility into industrial operations. Technologies such as renewable energy sources, energy-efficient systems, and green manufacturing processes will be prioritised. Industry 5.0 envisions a future where sustainable practices are inherent to every step of the production process.

- Augmented Intelligence. While Industry 4.0 introduced AI for automation, Industry 5.0 introduces augmented intelligence, which is a more collaborative form of AI where machines assist humans in decision-making processes. By analysing data in real-time, machines provide insights that empower human operators to make more informed and effective decisions, particularly in complex and creative tasks.

- Resilience and Flexibility. Industry 5.0 encourages resilience in operations by creating flexible production systems. Businesses are required to be more adaptable, focusing on agile methodologies and the ability to pivot rapidly in response to market changes, supply chain disruptions, or technological advancements.

The Differences Between Industry 4.0 and Industry 5.0

While Industry 4.0 is primarily focused on automation and data exchange within manufacturing systems, Industry 5.0 introduces a human element into the equation. Here are some major differences:

- Industry 4.0: Automation, IoT, AI, and big data are used to create smart factories where machines can communicate and manage production with minimal human intervention.

- Industry 5.0: A human-centric approach where intelligent machines augment human capabilities. It aims to enhance creativity, offer personalised solutions, and achieve sustainability through human-machine collaboration.

Preparing for Industry 5.0

As Industry 5.0 becomes a reality, businesses need to take proactive steps to stay competitive in this human-centric future. Here are key strategies to prepare.

-

Invest in Human-Centric Technology.

The core of Industry 5.0 is the synergy between human talent and technology. To prepare, businesses should start investing in cobots and human-machine interface tools that enable collaboration between workers and machines. This includes intuitive user interfaces, real-time data dashboards, and wearable technologies that assist workers in decision-making.

-

Upskill and Reskill the Workforce.

Industry 5.0 requires a workforce that not only knows how to operate machines, but also how to problem-solve, be creative, and collaborate. Companies need to focus on upskilling and reskilling employees so they can work effectively alongside machines. Investing in training programs that focus on advanced digital literacy, creative thinking, and technical skills will be critical. The alternative is to hire augmented specialists you need.

-

Focus on Sustainability.

With environmental sustainability a key feature of Industry 5.0, companies should implement greener practices across their operations. This includes using renewable energy, reducing waste, optimising resource efficiency, and embracing circular economy principles. Preparing for this shift means assessing your environmental impact and finding ways to reduce your carbon footprint across the entire value chain.

-

Embrace Personalisation.

Mass customisation will be a major driver of Industry 5.0, so companies need to focus on personalising their offerings. Whether it’s customising products, services, or customer experiences, using data analytics and customer insights to offer customised solutions will be key to staying relevant. Personalisation also means being flexible in production and adapting to customer needs in real time.

-

Embrace Agile Manufacturing.

Industry 5.0 will require manufacturers to be highly adaptable. Traditional rigid production lines will give way to flexible manufacturing systems that can quickly switch between products and respond to market demands. Investing in modular and scalable manufacturing systems that allow for rapid reconfiguration is a smart move to future-proof your business.

-

Strengthen Cybersecurity Measures.

As humans and machines collaborate more deeply, data security becomes even more important. Companies must ensure that their digital infrastructure is secure and sensitive data is protected. Advanced cybersecurity systems and protocols must be implemented to prevent potential vulnerabilities arising from increased connectivity.

-

Create Collaborative Ecosystems.

Industry 5.0 thrives on collaboration not only between humans and machines, but also between different companies and industries. Businesses should work to create partnerships and ecosystems that foster innovation and knowledge sharing. Collaboration with external experts, research institutes, and technology providers can accelerate the adoption of Industry 5.0 principles and solutions.

The Role of Leadership in Preparing for Industry 5.0

Leadership will play a critical role in shaping the future of Industry 5.0. Executives and decision makers must understand the significance of this transformation and be prepared to lead their organisations through this transition. This means cultivating a culture of innovation, investing in the right technologies, and equipping employees with the skills they need to succeed.

Leadership must also focus on creating a human-centric work culture that values creativity, collaboration, and continuous learning. Creating such an environment will be vital for employees to embrace the changes that Industry 5.0 brings and for businesses to realise the full potential of human-machine collaboration.

Conclusion

Industry 5.0 represents a new industrial era where humans and machines work together harmoniously, creating personalised products and services while driving sustainability and resilience. By preparing now, businesses can position themselves to succeed in this human-centric future.

Investing in human-machine collaboration technologies, upskilling the workforce, focusing on sustainability, and adopting flexible and personalised production processes are essential steps for embracing Industry 5.0. As businesses move toward this new horizon, the role of leadership will be paramount in guiding teams through this transformation, ensuring that they are ready to thrive in the age of human-centric innovation.