Project Summary

InStandart developed a realistic operator training simulator for an air separation unit (ASU). Using the client’s detailed 3D model, P&IDs, and PFDs, we created an interactive simulator using Unity. The goal was to replicate real plant conditions and processes to safely, repeatably train operators without the risks associated with live equipment.Business Challenges

The client faced several operational challenges related to plant training and safety:

- High onboarding risk: Inexperienced operators had difficulty understanding complex ASU systems during live training, leading to frequent procedural errors and safety risks.

- Expensive training downtime: Real equipment had to be temporarily shut down or isolated for training, disrupting productivity and increasing operating costs.

- Inconsistent training: Traditional classroom training and static diagrams could not fully convey the dynamic behavior of the plant, leading to gaps in operator preparedness.

- Lack of emergency scenario practice: Operators did not have the opportunity to experience rare but critical emergency situations such as valve failures or pressure surges, as such events could not be safely simulated on site.

Solution

InStandart developed a customized operator training simulator with the following capabilities:

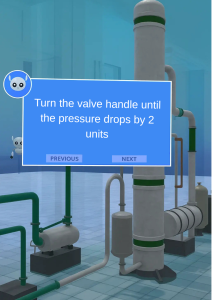

- 3D Plant Environment: Built on Unity, the simulator utilized the customer’s detailed 3D model to create a realistic and user-friendly virtual environment that mirrored the actual ASU layout.

- A specially trained AI model that dynamically simulated the behavior of the ASU in real time, responding intelligently to both operator actions and internal system changes.

- Interactive Training Modes: Enabled operators to practice standard operating procedures (SOPs), emergency shutdown sequences, and fault response.

- Scenario-Based Training: Included customizable scenarios such as oxygen purity drop, power loss, and cryogenic leaks, with step-by-step assessment and feedback.

- User Interface: Intuitive controls and dashboards were developed for trainees to interact with instruments, valves, and dashboards.

- Performance Tracking: Built-in analytics engine tracked user actions, errors, and resolution times for personalized feedback and team assessment.

Results

| Training KPI | Before Integration | After Integration |

| Operator training time | 4–6 weeks | 2–3 weeks |

| Incidents during onboarding | Moderate | Reduced by 80% |

| Training cost per operator | High (due to live equipment) | Reduced by 60% |

| Retention of operating procedures (measured post-training) | ~60% | >90% |

| Emergency response preparedness (simulated tests) | Low | Improved by 70% |

Additional benefits:

- Increased operator confidence and response times under both normal and abnormal conditions.

- Remote training capability, reducing travel and congestion on site.

- Ability to provide safe, repeatable training with no risk to personnel or equipment.

- Improve HSE compliance and audit readiness with digital training logs.