Project description

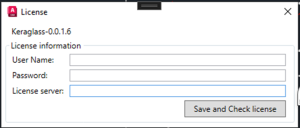

This CAD project's main objective is to automate the preparation of a drawing for subsequent transfer to a glass embossing printer. As part of the project, a system was developed to automatically draw a set of circles according to specified parameters along the contour of the glass. The software stores the parameters within the drawing without using any additional files or resources. A parameter import/export system has been implemented. Additionally, a licensing system (network licenses) has been implemented.Project summary

|

Industry: Glass embossing |

Business goals: automate the preparation of a drawing for subsequent transfer to a glass embossing printer |

|

Team: 1 developer, 1 project manager |

Applied technologies: C#, .NET WPF, .NET AutoCAD API, Windows Forms |

Business Challenge

In the glass embossing industry, preparing drawings for printing onto glass surfaces traditionally involved manual processes that were time-consuming and prone to errors. Engineers had to meticulously design patterns and layouts for each project, resulting in significant delays and inefficiencies.

Additionally, managing parameters and ensuring consistency across designs posed challenges. We identified these pain points and sought to develop a solution to automate drawing preparation, streamline processes, and enhance efficiency.

Solution

To address the challenges faced by the glass embossing industry, we developed a cutting-edge software solution designed to automate the drawing preparation process. The system, integrated as a plug-in within the AutoCAD environment (compatible with AutoCAD 2020 – AutoCAD 2024 on Windows OS), aimed to simplify and expedite the creation of drawings for glass embossing printers.

The software offers several key functionalities to facilitate drawing preparation:

- Fill Area with Solid Pattern: This feature enables users to efficiently fill closed polylines with solid hatches, eliminating the need for manual filling. Users can select polylines, and the application automatically fills them with a solid hatch, enhancing speed and accuracy in the drawing preparation process.

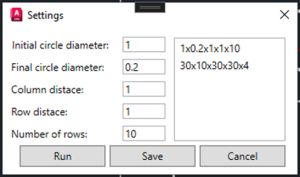

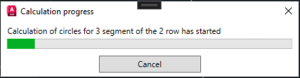

- Create Pattern Rows: This command revolutionizes the creation of patterns by automating the generation of specified rows of circles along the contour of the glass. Users select a polyline and designate a side for offset. They can then specify parameters such as start circle diameter, end circle diameter, distance between circles, distance between rows, and the number of rows. The software seamlessly generates the specified number of rows of circles with the designated parameters, significantly reducing the time and effort required for pattern creation.

Furthermore, the software incorporates a parameter import/export system, allowing users to save and reuse parameters for future projects. This enhances consistency and efficiency across designs, streamlining workflow processes. Additionally, a robust licensing system, offering network licenses, ensures seamless access and management for users within an organization.

Delivered Results

The implementation of the software has brought about transformative results:

- Enhanced Efficiency: By automating drawing preparation processes, the software has significantly reduced the time required for pattern creation, enabling engineers to generate designs swiftly and efficiently.

- Improved Accuracy: Automation has minimized human errors inherent in manual processes, ensuring greater precision and consistency in design output.

- Streamlined Workflow: The parameter import/export system facilitates the reuse of parameters, promoting standardization and efficiency across projects. Moreover, the licensing system simplifies access and management, enhancing workflow coherence within organizations.